STP MAGIS CNC

OVERVIEW

Unmatched repeatability and quality will further increase efficiency and profitability.

Speed, precision and ease of use are only some of the features of the innovatively designed STP Magis CNC system.

STP Magis allows obtaining measurement results independently of the operator.

CALCULATE YOUR RETURN ON INVESTMENT

Highlights

- HOMOGENEOUS STRUCTURE

- COMPACT SIZE

- UNPARALLELED PRECISION

- UNRIVALED PRICE/PERFORMANCE RATIO

- MANUAL AND AUTOMATIC AXES MOVEMENT

- AUTOMATIC SPINDLE MOVEMENT

- AUTOMATIC MECHANICAL CLAMPING OF THE TOOLHOLDER

- PC AND CONTROLS FROM THE BEST MANUFACTURERS

- LINEAR GLASS SCALES

- CMOS CAMERAS

- TELECENTRIC OPTICS

- HIGH QUALITY PNEUMATIC COMPONENTS

- DATA OUTPUT (POST PROCESSOR)

- NETWORK CONNECTION

- ONLINE HELP FUNCTION

- INDUSTRY 4.0 READY

CHOOSE THE BEST STP MAGIS CNC FOR YOUR NEEDS

| AXES RANGE | STP MAGIS 400 TEST EN | STP MAGIS 600 |

| length | 400 mm | 600 mm |

| diameter and snap gage | 350 / -50 mm | 350 / -50 mm |

| diameter & snap gage* | 400 / 0 mm | 400 / 0 mm |

| *optional |

100% AUTOMATIC

You can automatically execute measuring cycles, thus removing the human error factor.

MAXIMUM ERGONOMICS

The ergonomic structure of the STP Magis systems shows the attention palced to the human factor.

The design efforts have always delivered unmatched ergonomic solutions.

GUARANTEE OF PRECISION

The numeric control system allows for the operator-independent, fast and μ-precise positioning of the axes.

FEATURES

Automatic spindle and X and Z axes movement

Automatic spindle and X and Z axes movement

X and Z axes manual movement always available

X and Z axes manual movement always available

Functional cockpit

Functional cockpit

Hi-Res camera with 45X magnification optics

Hi-Res camera with 45X magnification optics

Front light for cutting edge inspection

Front light for cutting edge inspection

Structure in aged pearlitic cast iron that guarantees maximum isostaticity.

Structure in aged pearlitic cast iron that guarantees maximum isostaticity.

Ergonomic workbench with choice of cockpit positioning

Ergonomic workbench with choice of cockpit positioning

22″ Standard Monitor

22″ Standard Monitor

Ergonomic cockpit with integrated monitor support

OPTIONAL

Additional swing-arm camera with LED front light

Additional center-height camera with LED front light

Y axis manual movement device

Y axis manual movement device

Spindle indexing function to set the position in 4×90°

Spindle indexing function to set the position in 4×90°

Advanced dialogue with NC machines available via RFID systems, barcodes, QR codes, network and more.

Advanced dialogue with NC machines available via RFID systems, barcodes, QR codes, network and more.

Advanced dialogue with NC machines available via RFID systems, manually managed

Advanced dialogue with NC machines available via RFID systems, manually managed

24″ or 27″ Touch Screen HD Monitor

Thermal alphanumeric label printer and dedicated shelf

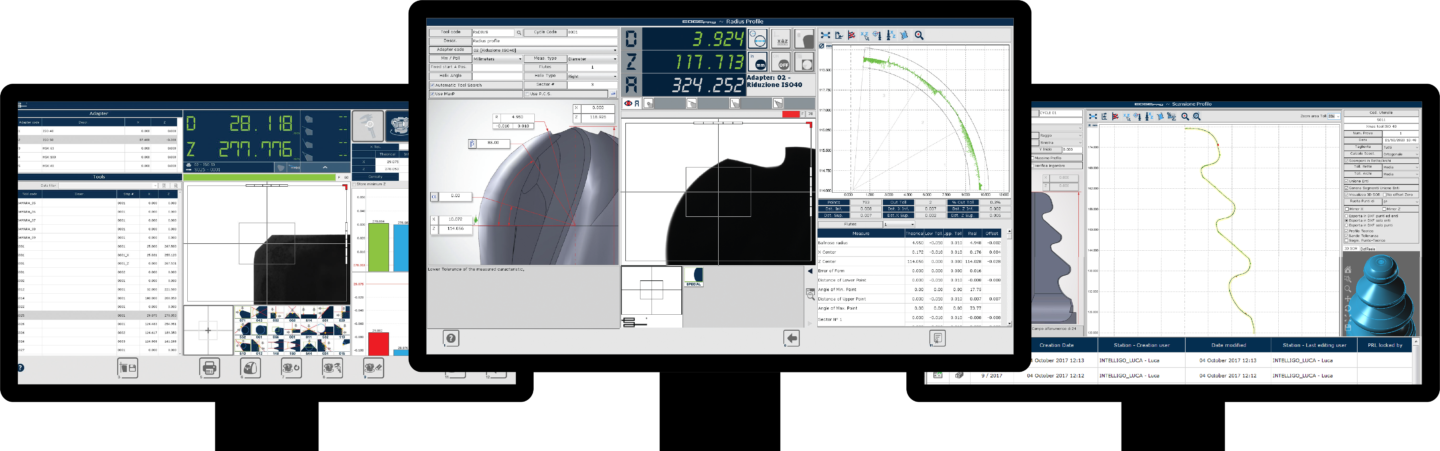

Software

STP Magis CNC can be equipped with the Edge and Edge Pro Control series, the perfect solution for tool management and inspection, user management, CAM interfacing and for the complete control of manual and CNC configurations and Industry 4.0 integration.

THE SOFTWARE CONTROLS, ENTIRELY DESIGNED AND DEVELOPED BY SPERONI, DELIVER THE RIGHT SOLUTION FOR EVERY TOOL PRESETTING, MEASURING AND MANAGEMENT NEED.

Connectivity

Simple and safe tool data transfer to/from machine tools: advanced dialogue with NC machines is available via RFID systems, QR codes, network and more.

CAM and TMS integrations

Facilitates tool data sharing with CAM and TMS systems.

ALSO AVAILABLE

DOWNLOAD & MEDIA

EVALUATE YOUR INVESTMENT IN A PRESETTER

CONTACT US

NEED MORE INFORMATION?

Call us, send us an email or fill out the form: our Customer Service will contact you as soon as possible.